-

Tel:86-15176910262

Tel:86-15176910262

-

Search

erw tube mill manufacturer

Mar . 06, 2025 11:17

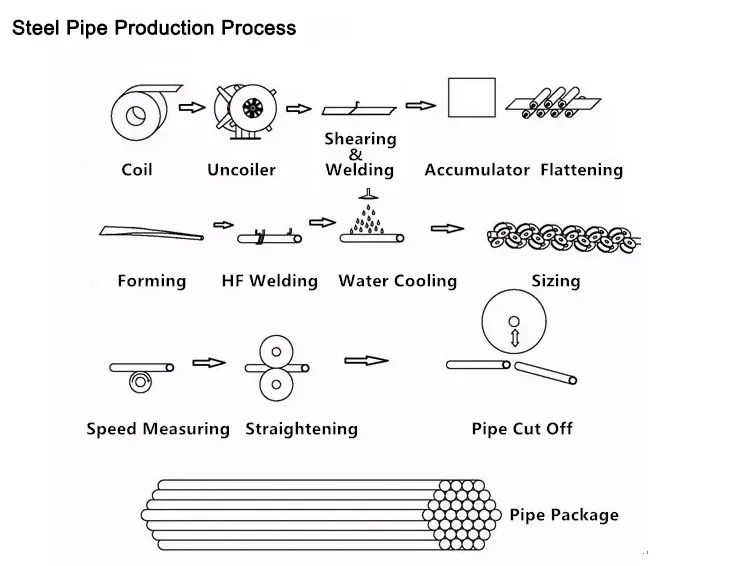

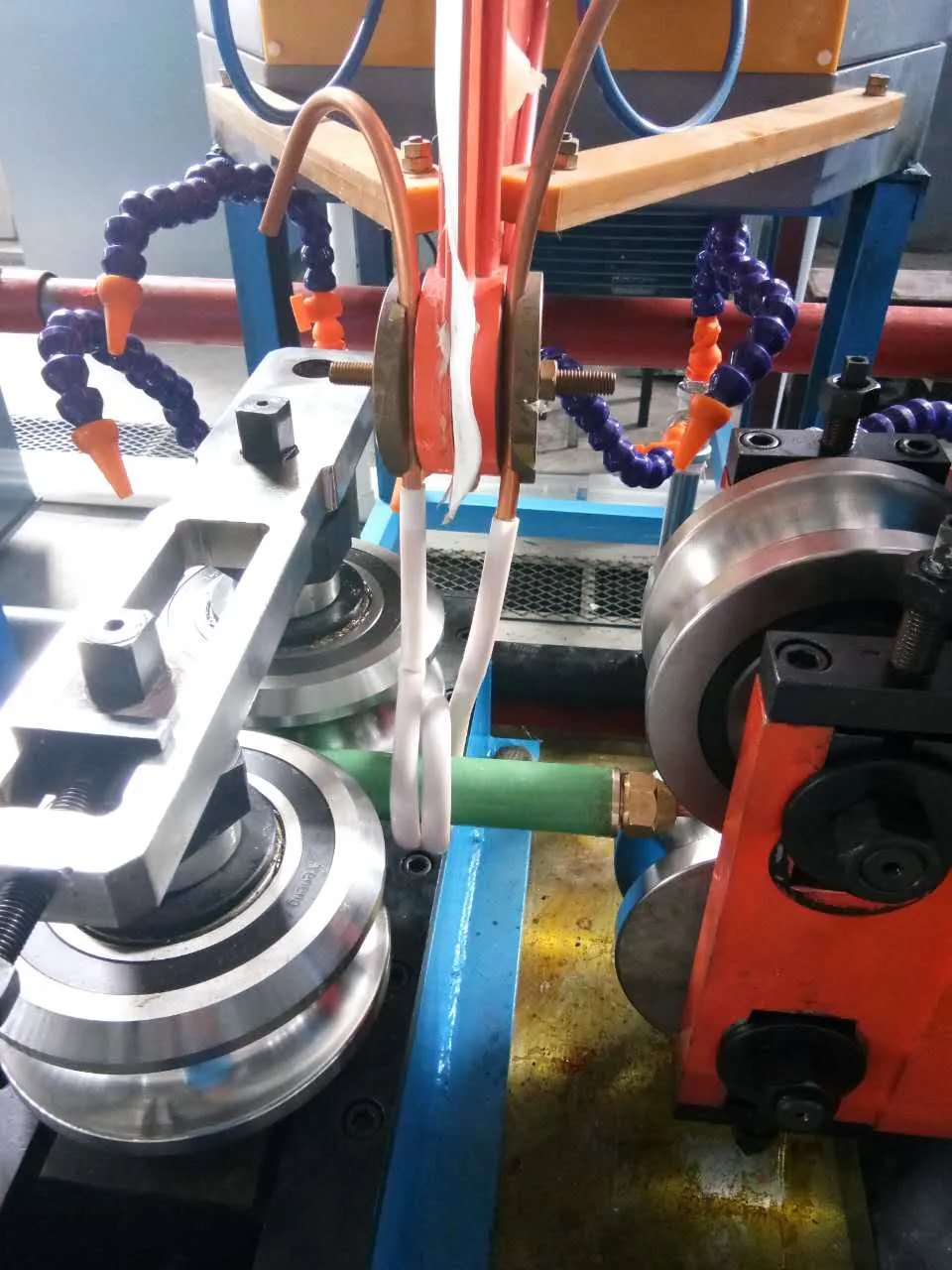

The world of manufacturing is vast, yet few sectors rival the precision and expertise required in the realm of ERW tube mill manufacturing. Companies producing this technology do not simply produce machinery; they create the backbone of numerous industrial and construction applications, requiring unparalleled expertise and trustworthiness. When considering an ERW tube mill manufacturer, understanding the intricacies of their operation is crucial for selecting a partner that ensures both product excellence and superior service.

Trustworthiness cannot be overstated in the manufacturing sector. The relationship between a buyer and an ERW tube mill manufacturer is built on transparency, reliability, and ethical business practices. Trustworthy manufacturers implement robust quality assurance processes and offer warranties that reflect confidence in their product's durability and performance. Furthermore, they engage openly in discussions about client concerns and seek to build long-term partnerships rather than executing one-off sales. Testimonials and client reviews provide further evidence of reliable, trustworthy business practices. In evaluating an ERW tube mill manufacturer, buyers should also consider their capacity for customization. The ability to tailor solutions to meet specific client needs demonstrates a manufacturer's flexibility and customer-oriented approach. This adaptability often results from a strong synergy between experience, expertise, and cutting-edge technologies, ensuring that each client receives a solution aligned perfectly with their operational requirements. Ultimately, choosing the right ERW tube mill manufacturer is a decision that rests on assessing these pillars of experience, expertise, authoritativeness, and trustworthiness. The selected partner should not only supply a high-quality product but also embody a reliable source of support and innovation. Through diligent research and a careful evaluation of these attributes, businesses can secure a manufacturer who is not just a supplier but a strategic partner in achieving sustainable success in their own ventures.

Trustworthiness cannot be overstated in the manufacturing sector. The relationship between a buyer and an ERW tube mill manufacturer is built on transparency, reliability, and ethical business practices. Trustworthy manufacturers implement robust quality assurance processes and offer warranties that reflect confidence in their product's durability and performance. Furthermore, they engage openly in discussions about client concerns and seek to build long-term partnerships rather than executing one-off sales. Testimonials and client reviews provide further evidence of reliable, trustworthy business practices. In evaluating an ERW tube mill manufacturer, buyers should also consider their capacity for customization. The ability to tailor solutions to meet specific client needs demonstrates a manufacturer's flexibility and customer-oriented approach. This adaptability often results from a strong synergy between experience, expertise, and cutting-edge technologies, ensuring that each client receives a solution aligned perfectly with their operational requirements. Ultimately, choosing the right ERW tube mill manufacturer is a decision that rests on assessing these pillars of experience, expertise, authoritativeness, and trustworthiness. The selected partner should not only supply a high-quality product but also embody a reliable source of support and innovation. Through diligent research and a careful evaluation of these attributes, businesses can secure a manufacturer who is not just a supplier but a strategic partner in achieving sustainable success in their own ventures.

Related Products

Related News

Send a Message

Dear customer, thank you for your attention! We provide high-quality machinery and equipment and look forward to your orders. Please inform us of your needs and we will respond quickly!