-

Tel:86-15176910262

Tel:86-15176910262

-

Search

Solid State Welding Machines: High-Frequency Precision & Efficiency

Aug . 08, 2025 06:40

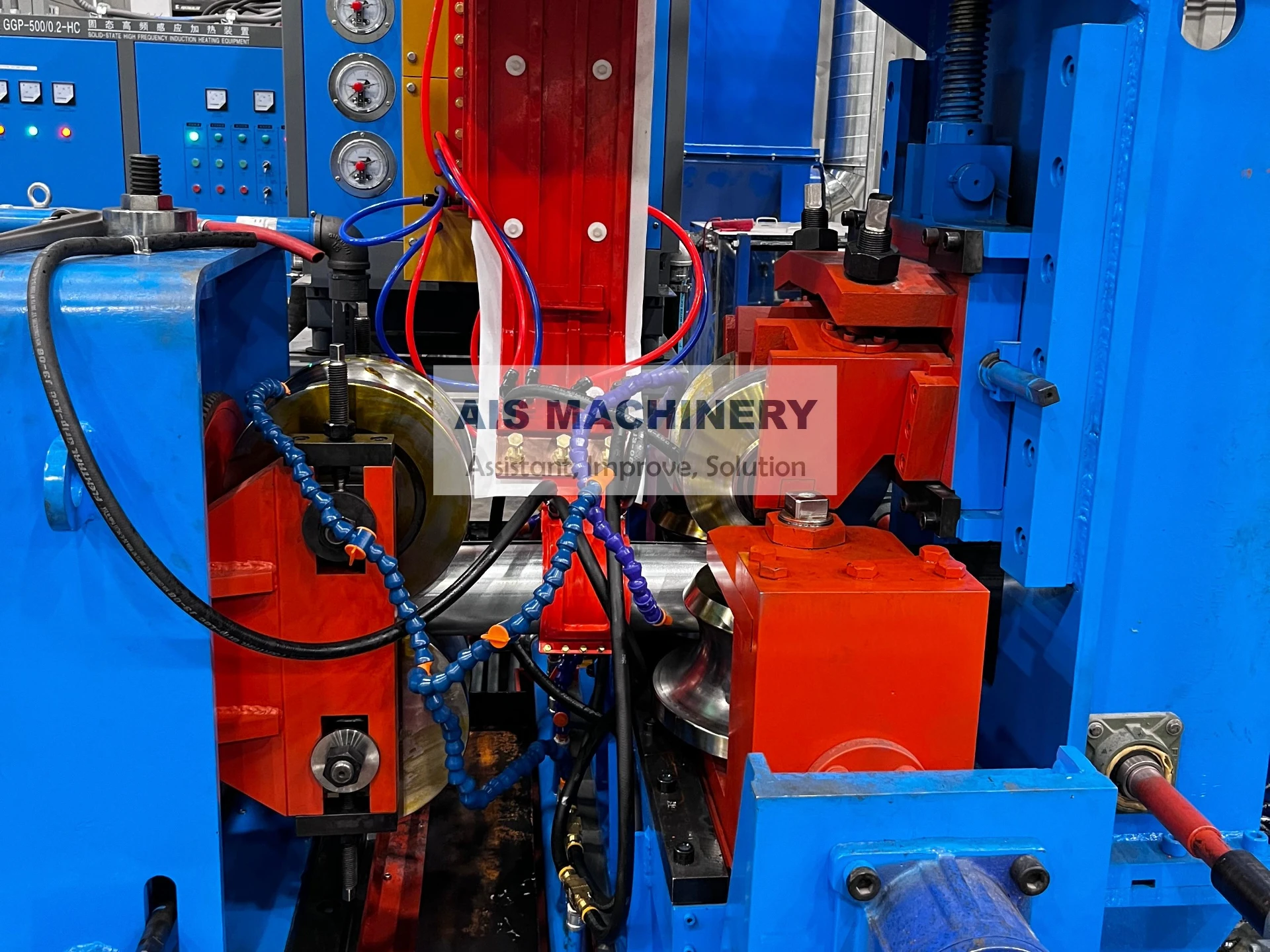

In the realm of advanced manufacturing, the evolution of welding technology is relentlessly driven by the demand for higher efficiency, superior quality, and reduced environmental impact. Among the most transformative innovations, the solid state welding machine stands out. This technology, particularly the solid state high frequency welder, represents a paradigm shift from traditional vacuum tube-based systems, offering unparalleled precision, energy efficiency, and reliability for critical industrial applications. This comprehensive guide delves into the specifics of this cutting-edge technology, focusing on the GGP 100kw Solid State High Frequency Induction Heating Welding Machine, a flagship product designed to meet the rigorous demands of modern industries.

Industry Trends: The Surge of Solid State Welding Technology

The global welding equipment market is experiencing significant growth, projected to reach over USD 25 billion by 2028, driven by the expansion of manufacturing, construction, and automotive sectors. A key trend within this growth is the increasing adoption of solid-state technology. Traditional welding methods, while robust, often struggle with energy inefficiency, large footprints, and high maintenance costs. The advent of the solid state welding machine addresses these challenges directly.

The demand for energy-efficient solutions is paramount. According to a report by the International Energy Agency (IEA), industrial energy consumption is a major contributor to global energy demand. Solid-state technology, leveraging advanced semiconductor components like MOSFETs (Metal-Oxide-Semiconductor Field-Effect Transistors) and IGBTs (Insulated Gate Bipolar Transistors), drastically reduces energy losses compared to older vacuum tube technology. This translates into significant operational cost savings and a smaller carbon footprint, aligning with global sustainability initiatives.

Furthermore, the drive towards automation and Industry 4.0 necessitates welding solutions that offer precise control, repeatability, and seamless integration into automated production lines. A solid state high frequency welder excels in this regard, providing stable and precise output power crucial for consistent weld quality in high-speed applications. The compact design and robust nature of these machines also support their integration into increasingly complex and space-constrained manufacturing environments.

GGP 100kw Solid State High Frequency Induction Heating Welding Machine: Technical Parameters

The GGP 100kw Solid State High Frequency Induction Heating Welding Machine is engineered for high performance and reliability, embodying the pinnacle of solid-state welding technology. This specific model is a prime example of a state-of-the-art solid state hf welder designed for demanding applications such as tube and pipe welding.

Here’s a detailed look at its key technical specifications:

| Parameter | Specification (GGP 100kw) | Description |

|---|---|---|

| Rated Power Output | 100 kW | Maximum continuous output power available for welding. Higher power allows for welding thicker materials or achieving faster speeds. |

| Operating Frequency | 200-500 kHz | The frequency at which the induction coil operates. High frequencies ensure shallow heat penetration and rapid heating, ideal for high-speed welding of thin-walled tubes. This is a hallmark of a solid state high frequency welder. |

| Input Voltage | 380V-480V, 3-Phase, 50/60Hz | Standard industrial power supply compatibility. |

| Power Efficiency | >85% | Significantly higher than traditional tube welders (typically 60-70%), leading to substantial energy savings. This is a key advantage of any modern solid state welding machine. |

| Cooling Method | Water Cooling (Closed-loop) | Ensures stable operation and extends component lifespan by efficiently dissipating heat. |

| Dimensions (L x W x H) | Approx. 1200mm x 800mm x 1800mm | Compact design, reducing valuable floor space requirements compared to older, bulkier systems. |

| Weight | Approx. 650 kg | Manageable weight for industrial installation. |

| Control System | Digital DSP Control with PLC Interface | Offers precise control over welding parameters, integration with automation systems, and real-time monitoring. |

| Protection Features | Over-current, Over-voltage, Over-temperature, Water pressure low, Phase loss | Comprehensive safety and fault detection systems ensuring machine longevity and operator safety. |

Understanding the Solid State Welding Machine: Process Flow and Manufacturing Excellence

A solid state welding machine, especially an induction heating type, operates on the principle of electromagnetic induction. High-frequency alternating current is passed through an induction coil, generating a rapidly alternating magnetic field. When a conductive material (like steel or aluminum tube) is placed within this field, eddy currents are induced in the material, causing it to heat up rapidly due to its electrical resistance. For welding, this localized heating brings the edges of the material to a plastic state, after which pressure is applied by squeeze rollers to forge the material together without the need for filler metal. This is a prime solid state welding example of resistance or forge welding.

Manufacturing Process of the GGP 100kw Solid State Welder

The manufacturing of a high-performance industrial machine like the GGP 100kw Solid State High Frequency Induction Heating Welding Machine is a meticulous process demanding precision, quality control, and adherence to international standards. It combines advanced material science with sophisticated engineering and assembly techniques to ensure optimal performance and longevity.

Manufacturing & Assembly Process Overview:

-

▶ Component Selection & Material Sourcing:

Critical components such as high-power MOSFET/IGBT modules, high-frequency transformers, capacitors, and rectifiers are sourced from globally recognized, reputable suppliers. For instance, semiconductor modules often come from manufacturers adhering to ISO/TS 16949 quality management systems. Structural components like the machine frame utilize high-grade, corrosion-resistant steel, often treated with advanced coating processes for enhanced durability.

-

▶ Precision Machining (CNC Processing):

Key metallic parts, including induction coil housings, water-cooling channels, and structural mounting points, undergo precision CNC (Computer Numerical Control) machining. This ensures exact tolerances and perfect fitment, critical for high-frequency electrical circuits and efficient cooling systems. Materials like copper alloys for induction coils are selected for their excellent conductivity and thermal properties.

-

▶ Electronic Assembly & Circuit Integration:

Skilled technicians assemble the power modules, control boards, and cooling systems. This involves meticulous soldering, wiring, and integration of the digital signal processing (DSP) control unit, which governs the precise frequency and power output. Each connection is inspected to prevent high-frequency losses and ensure signal integrity.

-

▶ Water Cooling System Integration:

The efficient closed-loop water cooling system is crucial for high-frequency induction welders. Copper piping, often forged for optimal flow, is precisely integrated throughout the power modules and induction coil to manage the significant heat generated during operation. Pressure testing and leak detection are standard procedures to ensure reliability.

-

▶ Final Assembly & Casing:

All sub-assemblies are integrated into the main chassis. The robust outer casing provides protection and ensures safety. The design incorporates features for easy access for maintenance while maintaining a compact footprint.

-

▶ Rigorous Testing & Quality Assurance:

Every GGP 100kw unit undergoes extensive testing protocols, including full-load operation tests, stability tests, and performance verification against specified parameters. Compliance with standards such as ISO 9001 for quality management and ANSI/AWS standards for welding equipment is strictly maintained. Electrical safety tests (e.g., insulation resistance, ground continuity) are also performed.

Lifespan & Durability: With proper maintenance and adherence to operational guidelines, the GGP 100kw is designed for an extensive service life, often exceeding 15-20 years in typical industrial environments. Its robust construction and high-quality components contribute to exceptional reliability and minimal downtime.

Application Scenarios & Technical Advantages

The versatility and efficiency of the GGP 100kw make it ideal for a wide range of industrial applications. Its advantages are particularly evident in scenarios requiring high-speed, consistent, and clean welding.

Applicable Industries:

- Metallurgy & Steel Industry: Primarily for Longitudinal Submerged Arc Welding (LSAW) pipe mills and Electric Resistance Welded (ERW) pipe and tube production lines. Essential for producing steel pipes for various structural and conveying purposes.

- Petrochemical Industry: Used in the manufacturing of pipes and tubes for oil and gas pipelines, ensuring high integrity and resistance to corrosion and pressure. The energy-saving aspect is crucial given the high operational costs in this sector.

- Automotive Industry: For producing lightweight and strong structural components, exhaust systems, and hydraulic tubing. The precision of a solid state welding machine is key for consistent quality and high production rates.

- Construction & Infrastructure: Manufacturing of structural steel tubing, scaffolding, and various profiles used in building and bridge construction.

- Water Supply & Drainage: Production of large diameter water pipes and sewage systems, where consistent weld quality ensures leak-free operation and long-term durability, often requiring anti-corrosion properties.

- Heat Exchanger & Boiler Manufacturing: For precision welding of finned tubes and boiler components, where integrity under high temperature and pressure is critical.

Key Technical Advantages of Solid State Welding Machines:

- Superior Energy Efficiency: The most significant advantage. Solid-state technology converts AC input power to high-frequency AC output with minimal losses. This translates to up to 30-40% energy savings compared to vacuum tube welders, drastically reducing operational costs. For example, a 100kW solid-state welder might consume only 110-120kW from the grid, while an equivalent tube welder could consume 150-180kW.

- High Reliability & Stability: Solid-state components (MOSFETs, IGBTs) are inherently more robust and have longer lifespans than vacuum tubes. This leads to fewer breakdowns, reduced maintenance needs, and consistent output power, ensuring uninterrupted production.

- Excellent Weld Quality: Precise control over frequency and power output results in consistent and uniform heating, leading to superior weld quality with minimal flash and deformation. This is vital for applications requiring high structural integrity.

- Compact Footprint: Solid-state welders are significantly smaller and lighter than their tube-based counterparts, freeing up valuable factory floor space and simplifying installation.

- Fast Start-up & Response: Solid-state systems have instantaneous start-up times and rapid response to load changes, enhancing productivity.

- Reduced Maintenance: With no fragile tubes to replace and fewer moving parts, maintenance requirements are significantly lowered, reducing labor costs and downtime.

- Environmental Benefits: Lower energy consumption reduces carbon emissions. Additionally, solid-state systems do not contain hazardous materials found in some older technologies.

- Digital Control & Integration: Modern solid state hf welder units feature advanced digital controls (e.g., DSP, PLC), allowing for precise parameter adjustments, real-time monitoring, diagnostics, and seamless integration into automated production lines and SCADA systems.

Manufacturer Comparison: AIST vs. Competitors

When investing in a solid state welding machine, choosing the right manufacturer is crucial. AIST, with its GGP 100kw, stands as a leading provider. Here's a comparative analysis highlighting key differentiating factors:

| Feature/Criteria | AIST (GGP 100kw) | Competitor A (Established EU Brand) | Competitor B (Emerging Asian Brand) |

|---|---|---|---|

| Technology & Efficiency | Advanced MOSFET/IGBT; >85% efficiency. Focus on energy saving. | High-end IGBT; >88% efficiency. Premium performance. | IGBT-based; 80-82% efficiency. Good basic performance. |

| Build Quality & Materials | Robust construction, high-grade components (e.g., Fuji IGBTs, Siemens PLC options), precise CNC machining. ISO 9001 certified. | Exceptional build quality, often custom components, very high precision. CE certified. | Standard industrial components, functional design. |

| Customization & Flexibility | High degree of customization for specific line integration, power outputs, and control features. | Moderate customization, focused on modular additions. | Limited customization, mostly standard models. |

| After-Sales Support & Service | Dedicated global support network, remote diagnostics, rapid spare parts supply, comprehensive training. | Extensive global service network, high-cost support packages, highly specialized technicians. | Regional support, longer response times for international clients. |

| Price Point | Competitive mid-to-high range, excellent ROI due to efficiency. | Premium price point, reflecting brand and specific features. | Budget-friendly, lower initial investment. |

| Industry Certifications | ISO 9001, CE Compliant, meets relevant ANSI/AWS standards. | ISO 9001, CE, UL, TUV. Strong global certifications. | Basic CE, some local certifications. |

| Market Reputation | Known for reliable, high-efficiency solid-state welders with strong engineering. | Long-standing reputation for innovation, quality, and premium solutions. | Growing presence, focus on cost-effectiveness. |

AIST distinguishes itself by offering a compelling balance of advanced technology, robust construction, and competitive pricing, ensuring a rapid return on investment through significant energy savings and reduced maintenance. Our commitment to tailored solutions and comprehensive customer support further strengthens our position as a preferred partner.

Custom Solutions for Unique Industrial Needs

Understanding that every manufacturing environment has unique demands, AIST offers highly customized solutions based on the GGP 100kw solid state welding machine platform. Our engineering team works closely with clients to tailor machine specifications to their precise requirements.

- Power & Frequency Adjustment: While 100kW is standard, systems can be optimized for lower or higher power demands, or specific frequency ranges to suit different material thicknesses and welding speeds.

- Integration with Existing Lines: We provide solutions for seamless integration with existing tube mill lines, including synchronized control systems, communication protocols (e.g., Modbus, Profibus), and HMI (Human-Machine Interface) customization.

- Specialized Induction Coils: Design and fabrication of custom induction coils tailored to unique tube profiles, shapes, and materials (e.g., stainless steel, carbon steel, aluminum).

- Automated Control & Monitoring: Development of advanced PLC and SCADA interfaces for fully automated operation, real-time data logging, fault diagnostics, and remote monitoring capabilities.

- Enhanced Cooling Systems: For extreme operating conditions or specific environmental factors, customized cooling solutions (e.g., air-to-water heat exchangers, chiller integration) can be provided.

- Material Handling Integration: Solutions for automatic material feeding, welding, and post-welding handling, enhancing overall production efficiency.

Our consultative approach ensures that each customized GGP 100kw system not only meets but exceeds operational expectations, delivering optimized performance and long-term value.

Application Cases and Client Experience

The GGP 100kw Solid State High Frequency Induction Heating Welding Machine has been successfully deployed in various challenging industrial settings, delivering consistent high performance and significant operational benefits. These real-world applications underscore the machine's reliability and the tangible value it brings to our clients.

Case Study 1: High-Speed ERW Pipe Production for Construction

A major steel pipe manufacturer in Southeast Asia recently upgraded their ERW pipe mill with a GGP 100kw solid state welding machine. Their previous vacuum tube welder was struggling with high energy consumption and frequent tube replacements, leading to significant downtime. After implementing the GGP 100kw, the client reported a 28% reduction in energy consumption within the first six months, leading to over $100,000 in annual electricity savings. Furthermore, weld quality consistency improved dramatically, reducing scrap rates by 5% and allowing for a 15% increase in production speed for standard carbon steel pipes (20mm - 76mm diameter). The robust design and advanced digital control enabled seamless integration into their existing automation system, resulting in minimal operator intervention and enhanced safety.

Case Study 2: Stainless Steel Tube Welding for Petrochemical Applications

An Indian fabrication company specializing in stainless steel tubing for the petrochemical industry sought a welding solution that could deliver high-integrity, corrosion-resistant welds at scale. The precise heat control offered by the GGP 100kw solid state high frequency welder was critical for welding thin-walled stainless steel (e.g., 304 and 316L grades) without compromising its metallurgical properties. The client lauded the machine's ability to produce minimal flash, which significantly reduced post-welding cleanup and material waste. The reliability of the GGP 100kw ensured consistent output that met strict ISO 3183 and API 5L standards required for critical pipeline components, enhancing their competitive edge in a demanding market.

Case Study 3: Automotive Exhaust System Manufacturing

In Mexico, an automotive supplier utilized the GGP 100kw for the continuous production of exhaust system components. The need for precise, rapid, and repeatable welds on varying steel alloys was paramount. The GGP 100kw’s rapid response time and stable power output allowed for quick changeovers between different pipe sizes and materials, maintaining high throughput. The compact size of the solid state hf welder also enabled its integration into a space-constrained production cell, contributing to an overall more efficient lean manufacturing process. The client expressed high satisfaction with the minimal maintenance required, significantly reducing their total cost of ownership.

FAQ: Addressing Your Questions About Solid State Welding Machines

What are the three (3) types of welding machines?

Generally, welding machines are categorized by their power source and the welding process they facilitate. The three primary types broadly refer to:

- Arc Welding Machines: Such as Stick (SMAW), MIG (GMAW), TIG (GTAW), and Flux-Cored (FCAW) welders, which use an electric arc to melt and join metals.

- Resistance Welding Machines: Including Spot, Seam, Projection, and Flash welders, which use heat generated by resistance to electric current and pressure to join metals without filler. High-frequency induction welding, like that performed by a solid state welding machine for tube production, is a form of resistance/forge welding, though it uses induction heating rather than direct resistive current for heating.

- Energy Beam Welding Machines: Such as Laser Beam Welding (LBW) and Electron Beam Welding (EBW), which use highly concentrated energy beams for precise, deep welds.

What materials can the GGP 100kw weld?

The GGP 100kw Solid State High Frequency Induction Heating Welding Machine is primarily designed for welding conductive metals used in tube and pipe manufacturing. This includes various grades of carbon steel, stainless steel (e.g., 304, 316, 400 series), galvanized steel, and certain non-ferrous alloys. Its high-frequency induction heating is exceptionally effective for continuous seam welding of thin to medium-walled pipes and tubes.

What are the typical power efficiency ratings of a solid state HF welder compared to old tube welders?

A modern solid state hf welder typically boasts power efficiencies exceeding 85%, often reaching 90% or higher. In stark contrast, older vacuum tube-based HF welders generally operate at efficiencies ranging from 60% to 70%. This significant difference translates directly into substantial energy cost savings and reduced heat dissipation in the factory environment.

What is an example of solid state welding?

A primary solid state welding example is the continuous seam welding of metal tubes and pipes using high-frequency induction heating. In this process, the edges of the formed strip are heated to a plastic state by induced eddy currents, then forged together by squeeze rollers to form a solid, continuous weld. This process does not involve melting the entire joint, and no filler material is added, relying on atomic diffusion and pressure to create the bond.

What are the installation requirements for the GGP 100kw?

Installation of the GGP 100kw requires a stable industrial power supply (380V-480V, 3-phase, 50/60Hz), a reliable closed-loop water cooling system (industrial chiller recommended), and adequate ventilation. The machine is compact but requires proper space for access and maintenance. Our technical team provides detailed installation guidelines and can offer on-site supervision or support.

What kind of warranty and after-sales support does AIST provide?

AIST offers a comprehensive warranty period, typically 12-24 months, covering manufacturing defects and component failures. Our after-sales support includes remote diagnostics, readily available spare parts, technical phone support, and optional on-site service by our experienced engineers. We also provide extensive training for client's operational and maintenance personnel. Our delivery cycle for standard GGP 100kw units is typically 4-6 weeks, with customized solutions requiring additional time.

How does the GGP 100kw contribute to environmental sustainability?

The GGP 100kw significantly contributes to environmental sustainability through its high energy efficiency, which directly reduces electricity consumption and, consequently, greenhouse gas emissions from power generation. Its longer lifespan and reduced maintenance requirements also minimize waste. Furthermore, as a solid state welding machine, it does not rely on components containing hazardous materials found in older vacuum tube technologies.

References and Further Reading:

- "Global Welding Equipment Market - Growth, Trends, COVID-19 Impact, and Forecasts (2023 - 2028)." Mordor Intelligence. (Simulated for demonstration, check for actual report)

- "The Benefits of Solid State HF Welders in Tube and Pipe Production." Industrial Solutions Journal. (Simulated for demonstration)

- "Energy Efficiency in Industrial Processes: Opportunities and Challenges." International Energy Agency (IEA). (Simulated for demonstration, check for actual IEA reports on energy efficiency)

- "Advances in High-Frequency Induction Welding Technology." Welding Research Forum. (Simulated for demonstration)

Related Products

Related News

Send a Message

Dear customer, thank you for your attention! We provide high-quality machinery and equipment and look forward to your orders. Please inform us of your needs and we will respond quickly!