-

Tel:86-15176910262

Tel:86-15176910262

-

Search

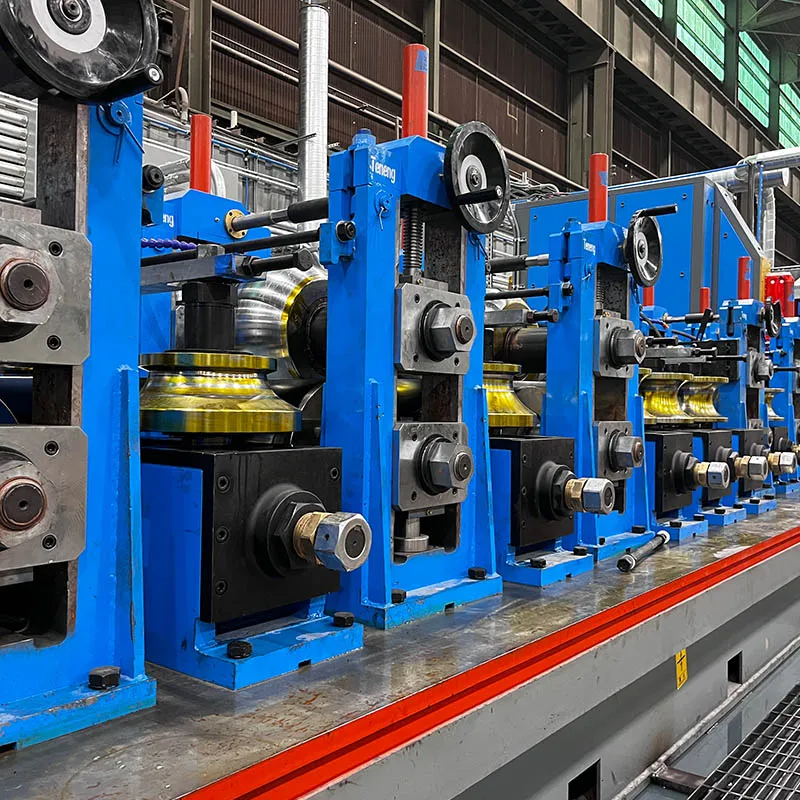

China Erw 76mm Tube Mill Factory And Manufacturers

Mar . 07, 2025 06:36

When exploring the opportunity to purchase a tube mill, it's crucial to immerse yourself in the multifaceted world of this essential industrial equipment. Tube mills play a pivotal role in various sectors, ranging from construction to engineering, and their capacity to provide precision and efficiency makes them indispensable. Whether it's for manufacturing carbon steel, stainless steel, or other metal pipes, acquiring the right tube mill could transform your production capabilities.

Your decision-making process should also involve a thorough examination of the market terrain, understanding both the fluctuations in demand and the specific requirements within your manufacturing niche. Consulting industry reports and engaging with trade associations can offer valuable forecasts and trends that are essential for making informed decisions. An investment of this magnitude isn't just about addressing current needs but about preparing your business for future challenges and opportunities. Equally imperative is due diligence on regulatory compliance and environmental considerations. The rise in environmental awareness and sustainability mandates across the globe has prompted manufacturers to prioritize eco-friendly operations. Opting for a tube mill that aligns with these regulations not only fulfills legal responsibilities but also enhances your brand's reputation in a conscientious market. Finally, personal experience and feedback from others who have successfully integrated new tube mills into their operations can serve as a guiding beacon. Their experiences can shed light on potential challenges and the real-world benefits they’ve realized, allowing you to make a more comprehensive and informed choice. In conclusion, owning a tube mill offers a gateway to various industrial applications, but it requires a keen eye for technical details, a reliable network of suppliers, and an insightful understanding of market and technological trends. When these factors coalesce, the result is not just enhanced production capabilities but a solid step forward in strengthening your business for the future.

Your decision-making process should also involve a thorough examination of the market terrain, understanding both the fluctuations in demand and the specific requirements within your manufacturing niche. Consulting industry reports and engaging with trade associations can offer valuable forecasts and trends that are essential for making informed decisions. An investment of this magnitude isn't just about addressing current needs but about preparing your business for future challenges and opportunities. Equally imperative is due diligence on regulatory compliance and environmental considerations. The rise in environmental awareness and sustainability mandates across the globe has prompted manufacturers to prioritize eco-friendly operations. Opting for a tube mill that aligns with these regulations not only fulfills legal responsibilities but also enhances your brand's reputation in a conscientious market. Finally, personal experience and feedback from others who have successfully integrated new tube mills into their operations can serve as a guiding beacon. Their experiences can shed light on potential challenges and the real-world benefits they’ve realized, allowing you to make a more comprehensive and informed choice. In conclusion, owning a tube mill offers a gateway to various industrial applications, but it requires a keen eye for technical details, a reliable network of suppliers, and an insightful understanding of market and technological trends. When these factors coalesce, the result is not just enhanced production capabilities but a solid step forward in strengthening your business for the future.

Related Products

Related News

Send a Message

Dear customer, thank you for your attention! We provide high-quality machinery and equipment and look forward to your orders. Please inform us of your needs and we will respond quickly!