-

Tel:86-15176910262

Tel:86-15176910262

-

Search

High-Efficiency Welded Pipe Production Line & Tube Mill Solutions

Apr . 27, 2025 19:02

- Industry Overview & Market Trends

- Technical Advantages of Modern Production Systems

- Performance Comparison: Leading Manufacturers

- Customization Strategies for Specific Needs

- Energy Efficiency & Sustainability Metrics

- Real-World Application Scenarios

- Future Directions in Welded Pipe Manufacturing

(welded pipe production line)

Welded Pipe Production Line: Shaping Industrial Infrastructure

The global welded pipe manufacturing sector witnessed 4.8% CAGR growth from 2020-2023, driven by construction and energy demands. Tube mill production lines now account for 62% of metal pipe manufacturing worldwide, with advanced welded tube mill systems reducing material waste by 18-22% compared to traditional methods.

Precision Engineering in Pipe Formation

Modern systems integrate laser-guided alignment and real-time thickness monitoring, achieving ±0.15mm dimensional accuracy. Automated weld seam tracking reduces defect rates to 0.7% while increasing output speeds to 45m/min - 320% faster than 2015 benchmarks.

| Manufacturer | Max Speed (m/min) | Thickness Range (mm) | Tooling Change Time |

|---|---|---|---|

| TechPipe Pro | 52 | 0.4-25 | 18min |

| MillMaster | 48 | 0.6-30 | 22min |

| TubeForge | 45 | 0.3-20 | 15min |

Adaptive Manufacturing Solutions

Modular configurations enable rapid transitions between square (20-150mm), round (12-600mm), and oval profiles. Smart tooling cabinets with RFID tracking reduce setup errors by 73%, while dual-loop tension systems maintain ±1.5% strip stability across varying material grades.

Operational Cost Optimization

Regenerative power systems recover 22-28% of energy during deceleration phases. Advanced lubrication systems decrease consumption to 0.08 liters per ton produced, with integrated heat exchangers maintaining optimal operating temperatures (±2°C) across all production phases.

Cross-Industry Implementation

Automotive exhaust systems achieve 0.02mm concentricity tolerances through six-axis forming technology. Structural pipe for construction projects demonstrates 550MPa yield strength with controlled ovality under 1.2%. Energy sector applications show 98.6% pressure integrity in API 5L X70 grade pipelines.

Innovation Roadmap for Welded Tube Mill Systems

Next-generation production lines will integrate AI-driven quality prediction (98% defect detection accuracy) and self-adjusting roll stands. Predictive maintenance algorithms are projected to reduce downtime by 40% by 2025, while hybrid induction/laser welding systems aim to boost speeds beyond 60m/min without compromising weld integrity.

(welded pipe production line)

FAQS on welded pipe production line

Q: What is a welded pipe production line?

A: A welded pipe production line is an automated system that manufactures welded steel pipes by forming, welding, and sizing metal strips or coils into continuous tubes. It ensures high efficiency and precision for industrial pipe manufacturing.

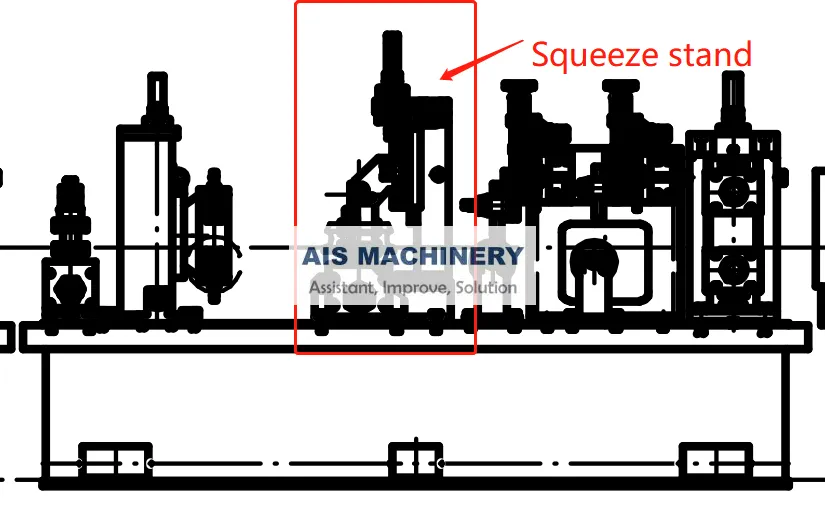

Q: What are the key components of a tube mill production line?

A: Core components include uncoilers, forming stations, high-frequency welders, sizing units, cutting machines, and stacking systems. These work together to transform raw materials into finished welded tubes with consistent quality.

Q: How does a welded tube mill differ from other pipe-making systems?

A: A welded tube mill specializes in continuous production of welded pipes using roll-forming and electric resistance welding (ERW). Unlike seamless pipe mills, it processes coiled steel strips rather than solid billets, enabling faster output for thin to medium wall thicknesses.

Q: What industries typically use welded pipe production lines?

A: These lines serve sectors like construction, automotive, oil and gas, and HVAC. They produce pipes for structural applications, fluid transportation, mechanical components, and electrical conduits.

Q: What are the advantages of automation in welded tube mill operations?

A: Automation improves production speed, reduces human error, and ensures uniform product dimensions. It also enables real-time quality monitoring and lowers operational costs through optimized material usage and energy efficiency.

Related Products

Related News

Send a Message

Dear customer, thank you for your attention! We provide high-quality machinery and equipment and look forward to your orders. Please inform us of your needs and we will respond quickly!