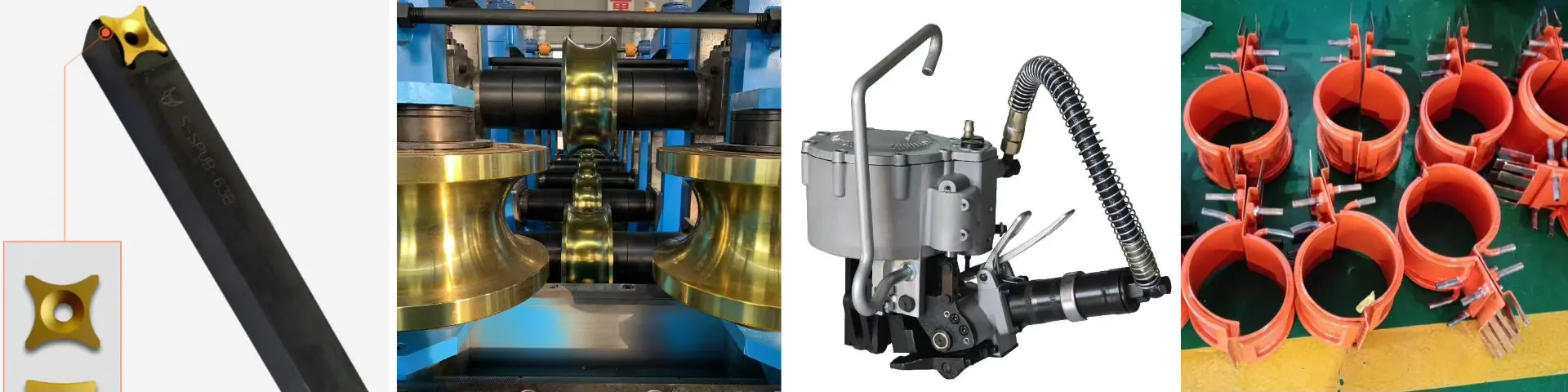

🔧 1. Slitting Knives

Slitting knives are the core cutting components used in slitting lines. They are designed to longitudinally slit wide steel coils into narrower strips. Suitable for a wide range of materials including stainless steel, carbon steel, galvanized steel, silicon steel, and aluminum.

Features:

-

Premium Materials: Commonly used materials include alloy tool steel and powder metallurgy high-speed steel (e.g., D2, SKD11, H13, Cr12MoV, ASP2053).

-

High Hardness: HRC 58–65 for excellent wear resistance and long service life.

-

Sharp Edges: Ensure clean cuts with minimal burrs.

-

Precise Heat Treatment: Delivers superior heat resistance and fracture toughness.

🧩 2. Slitting Spacers

Slitting spacers are placed between slitting knives to maintain consistent knife spacing and ensure precise slitting. They are essential for knife gap adjustment, positioning, and cushioning.

Features:

-

High Dimensional Accuracy: Tolerance up to ±0.001 mm.

-

Durable Materials: Typically made from high-hardness tool steel or stainless steel.

-

Surface Finishing: Includes black oxide, chrome plating, or nickel plating.

-

Various Types Available: Includes rubber spacers, metal shims, and solid precision spacers.

-

-

📊 Technical Specifications (Sample Table)

| Item |

Slitting Knife |

Slitting Spacer |

| Matériel |

D2 / Cr12MoV / SKD11 / H13 |

65Mn / Cr12 / Stainless Steel |

| Hardness (HRC) |

58–65 |

50–60 |

| Outer Diameter (mm) |

Ø80 – Ø500 |

Ø80 – Ø500 |

| Bore Tolerance |

H7 (customizable) |

H7 (customizable) |

| Thickness Range |

0.8 – 30 mm (customizable) |

0.5 – 20 mm (customizable) |

| Flatness |

≤0.002 mm |

≤0.0015 mm |

| Concentricity |

≤0.01 mm |

≤0.005 mm |

| Surface Finish |

Polished, Nitrided, Chrome-plated, etc. |

Nickel-plated, Blackened, Anti-rust oil |

🛠 Maintenance Guidelines

🔪 Slitting Knives

-

Regular Sharpness Check: Regrind when burrs appear or cutting quality declines.

-

Use Proper Cleaning Agents: Avoid metal debris buildup on the blade edge.

-

Storage: Keep knives separated using dedicated racks or boxes to avoid chipping.

-

Regrinding Schedule: Typically every 8–12 hours of cutting, depending on material hardness.

-

Avoid Overheating: Control cutting pressure and speed to prevent annealing or deformation.

🧩 Slitting Spacers

-

Avoid Scratches and Damage: Ensure spacer surfaces remain smooth for precise positioning.

-

Rust Prevention: Apply anti-rust oil regularly and clean before use.

-

Dimensional Calibration: Verify thickness when adjusting for different material gauges.

-

Labeled Storage: Store different thicknesses separately and clearly marked to prevent mix-up.

-

📊The comparison table for rubber-coated spacers, rubber rings, and washers used in steel coil slitting lines:

| Item |

Rubber-Coated Spacer |

Rubber Ring |

Washer / Shim |

| Purpose |

Installed between slitting knives to control slitting width and spacing, and to prevent coil surface damage |

Typically used for shock absorption, cushioning, or sealing gaps between tools/shafts |

Used for precise adjustment of slitting gaps or compensating dimensional deviations |

| Structure |

Metal spacer core coated with a rubber layer |

Entirely made of rubber in ring shape |

Made of metal, rubber, or composite material with high thickness precision |

| Matériel |

Composite of metal and rubber |

Rubber |

Commonly metal, but can also be rubber or plastic |

| Functional Features |

Prevents direct contact between tools, provides cushioning and protection |

Acts as a buffer, prevents loosening, and seals |

Ensures precise positioning and dimensional compensation |

| Thickness Range |

Generally several millimeters to over ten millimeters |

Thinner, primarily for elastic cushioning |

High precision, thickness can be controlled to 0.01 mm or less |

| Installation Location |

Mounted on the shaft between knives or spacers |

Installed at shaft or spacer interfaces |

Used where fine gap adjustment is required, e.g., between knives or shaft ends |

| Application |

Suitable for protecting coil edges and preventing damage |

Suitable for sealing or vibration-damping |

Suitable for fine-tuning dimensions or ensuring precise fit |

-

-

- 1. Coil car and Storage

- 2.Single And Double Heads Un-coiler & Hydraulic And Pneumatic Un-coiler

- 3.Peeler and hold down roll arm

- 4.Flattening Machine

- 5.Automatic and Semi Auto Shearer & Butt Welder

- 6.Vertical Cage Accumulator & Horizontal Loop Accumulator & Landing Horizontal Spiral Loop Accumulator

-

- 1. Machine à courants de Foucault

- 2. Seam annealing machine

- 3. Straightener machine

- 4. Chamfer and end facer machine

- 5. Hydro Tester machine

- 6. Threading machine

- 7. Painting and oil machine

- 8. Automatic bundle and package machine

Spare Parts and Consumble Parts

-

- 1. Rollers, Moulds, Dies, D2,D3 material to choose

- 2. Ferrite, Impeder, Fiberglass tube

- 3. HSS saw blades, TCT Saw blades, Friction saw blades

- 4. OD burr remove inserts, ID burr remover inserts

- 5. HF welder Induction Coil and other HF welder spare parts

- 6. Copper tube for induction Coil, PTFE pipe for Induction Coil

- 7. Mosfet, Boards

- 8. Steel pipe Strapping machine

- 9. Zinc Spray Machine, Zinc wire, Zinc spray gun

- Pourquoi nous choisir?

-

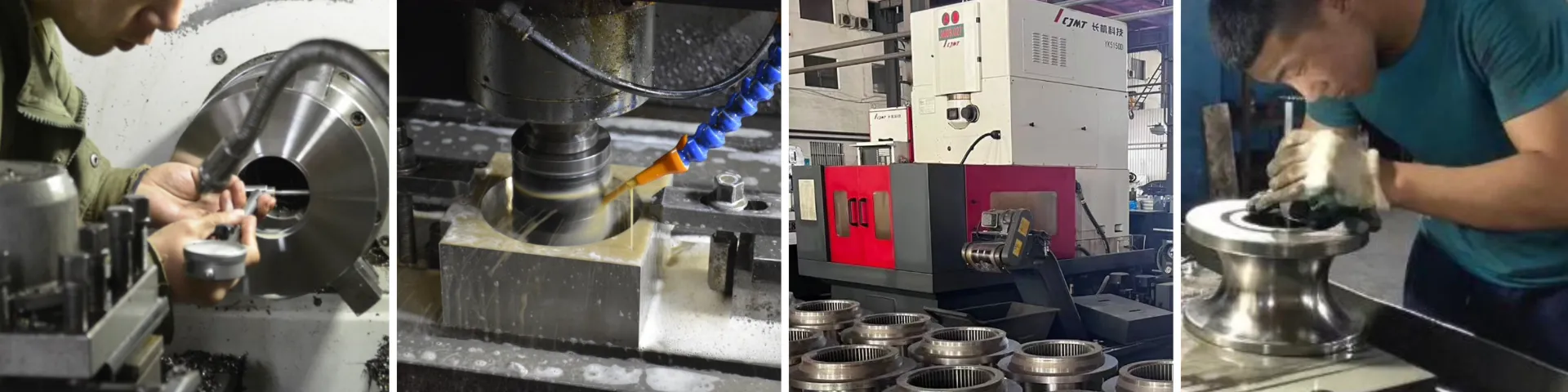

1.Leading Technology, Reliable Quality, Excellent Service! Conception optimisée, sélection de matériaux de haute qualité ! Garantie du processus de traitement thermique !

-

2.Spiral bevel gear, drum gear coupling and carburization. Trempe des dents d'engrenages. Système d'entraînement stable, efficace et portable avec moins de bruit.

-

3.High precision wear resisting and Long life of toolings. Tous les tours mécaniques, les rainures de clavette sont positionnés et fraisés par CNC.

-

4.Quality department make sure the material of the raw materials quality, and ensure the machine running perfect.

Service après-vente

- 1.Machine test running videos will supply to customer before shipment.

- 2.Online techenical support WHOLE LIFT FREE.

- 3.Professional engineers team to install the machine, train your employee well.

- 4.One year warranty and life-long technical support.

- 5,24 heures pour l'intervention de l'ingénieur.

- 6. Votre relation commerciale avec nous sera confidentielle envers tout tiers.

- 7. We welcome customers to visit our factory anytime.

Tel:86-15176910262

Tel:86-15176910262