Product Description

1. Overview & Working Principle 🛠️

-

Function: The Milling Saw—also called a profile milling flying saw—is mounted at the end of a longitudinal welded steel pipe production line. It precisely cuts continuously moving pipes to produce clean, burr-free ends.

-

Structure: Equipped with a servo-driven tracking system that synchronizes with pipe motion, it performs cold, profile milling cuts to deliver smooth, highly accurate cut faces.

2. Features & Components

-

Tracking System

-

Driven by a servo motor and using roller-speed measurement, it continuously monitors pipe velocity.

-

Controlled via an S-curve trajectory to achieve smooth, fine-tuned positioning of the saw head and precise cut locations.

-

Milling Cutting System

-

Operation Mode

-

Functions as a "flying saw": the cutter head moves along with the pipe, enabling high-speed cutting without stopping production.

-

Uses carbide or HSS blades to achieve cool, spark-free, low-noise operation while preserving pipe properties.

3. Typical Technical Specifications

| Parameter |

Typical Values / Notes |

| Pipe Diameter |

Typical range: Ø 16 mm to Ø 1000 mm (model-dependent) |

| Cutting Speed |

Commonly up to 80 m/min; some models exceed this |

| Cutting Tolerance |

Meets British BS standards; high dimensional precision |

| Cut-Face Quality |

Smooth and burr-free; typically requires no secondary chamfering |

| Blade Material |

High-speed steel (HSS), tungsten carbide tipped (TCT), etc. |

| Drive System |

Servo motors + multi-axis control (e.g. via controllers like Trio MC206) |

| Cutting Mode |

Dry cutting or wet cutting options available |

4. Advantages

-

High Precision: Combined with servo tracking and S-curve control, it meets international standards for cut positioning.

-

Excellent Cut Quality: Cold cutting produces smooth, burr-free ends without secondary finishing.

-

High Efficiency: Flying saw capability enables continuous operation without stopping the pipe line.

-

Low Noise & Dust: Cold cuts significantly reduce sparks and dust, creating a cleaner work environment.

-

Advanced Control: Multi-axis coordination and quality servo drives offer easy settings and tuning.

-

5. Daily Maintenance Tips

-

Blade Care

-

Regularly inspect blade wear and replace or regrind as needed to maintain quality.

-

Use recommended blade materials (HSS, TCT); avoid substandard blades that can damage pipes or equipment.

-

Drive & Servo System

-

Check cables, connectors, and sensors; remove dust, tighten fittings, and lubricate gears and rollers periodically.

-

Hydraulic & Pneumatic Systems

-

If equipped with wet cutting or air-control systems, inspect fluid, hoses, valves, and filters; clean regularly.

-

Control System Diagnostics

-

Cleaning & Housekeeping

-

Tool Setup Calibration

6. Summary

A profile milling flying saw for longitudinally welded steel pipes combines cold milling, servo tracking, and multi-axis control—ideal for high-speed, high-precision cutting. Its key benefits include burr-free cut faces, continuous production, efficient operation, and a cleaner work environment. To maintain performance and longevity, monitor blade condition, servo/control systems, cleanliness, lubrication, and alignment. Proper upkeep ensures consistent product quality and extends machine life. Let me know if you’d like actual model specs or a maintenance manual!

-

-

- 1. Coil car and Storage

- 2.Single And Double Heads Un-coiler & Hydraulic And Pneumatic Un-coiler

- 3.Peeler and hold down roll arm

- 4.Flattening Machine

- 5.Automatic and Semi Auto Shearer & Butt Welder

- 6.Vertical Cage Accumulator & Horizontal Loop Accumulator & Landing Horizontal Spiral Loop Accumulator

-

- 1. Eddy current machine

- 2. Seam annealing machine

- 3. Straightener machine

- 4. Chamfer and end facer machine

- 5. Hydro Tester machine

- 6. Threading machine

- 7. Painting and oil machine

- 8. Automatic bundle and package machine

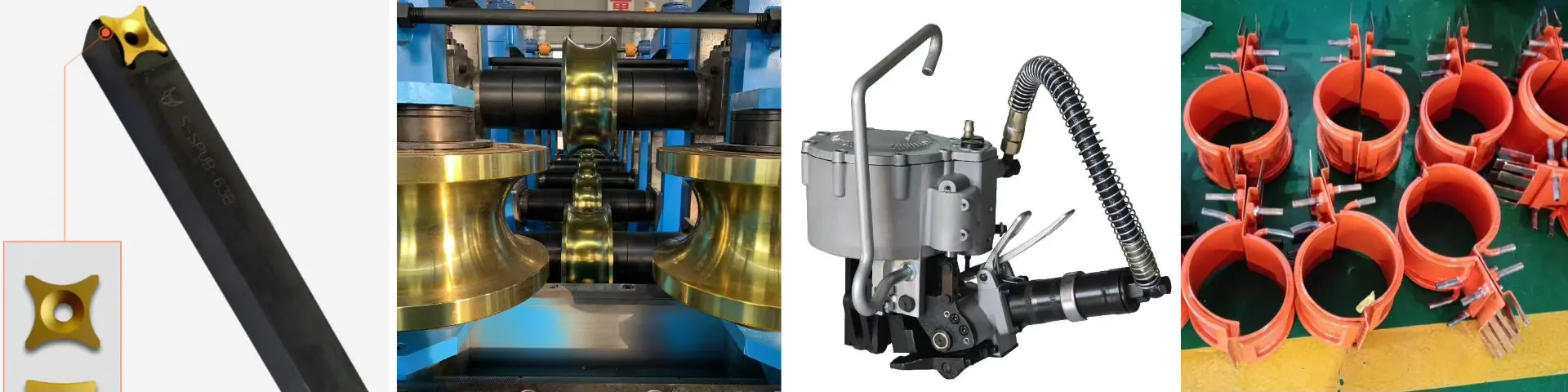

Spare Parts and Consumble Parts

-

- 1. Rollers, Moulds, Dies, D2,D3 material to choose

- 2. Ferrite, Impeder, Fiberglass tube

- 3. HSS saw blades, TCT Saw blades, Friction saw blades

- 4. OD burr remove inserts, ID burr remover inserts

- 5. HF welder Induction Coil and other HF welder spare parts

- 6. Copper tube for induction Coil, PTFE pipe for Induction Coil

- 7. Mosfet, Boards

- 8. Steel pipe Strapping machine

- 9. Zinc Spray Machine, Zinc wire, Zinc spray gun

- Why Choose Us?

-

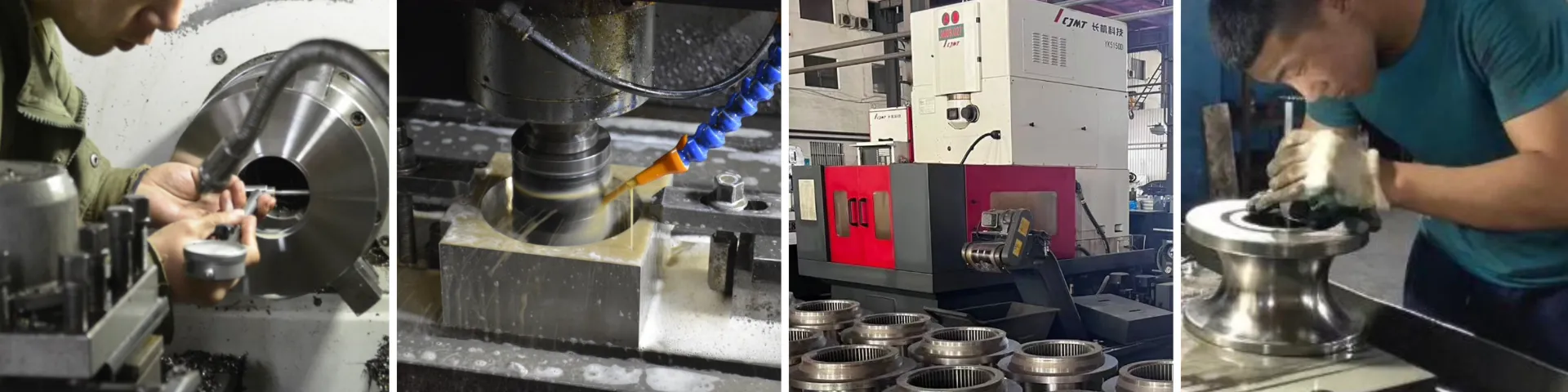

1.Leading Technology, Reliable Quality, Excellent Service! Optimized Design, High quality material select! Heat treatment process guarantee!

-

2.Spiral bevel gear, drum gear coupling and carburization. Gear teeth quenching. Driven system stable, efficient and wearable with lower noise.

-

3.High precision wear resisting and Long life of toolings. All the machine Lathes, Key Grooves are positioned and Milled by CNC.

-

4.Quality department make sure the material of the raw materials quality, and ensure the machine running perfect.

After-sales service

- 1.Machine test running videos will supply to customer before shipment.

- 2.Online techenical support WHOLE LIFT FREE.

- 3.Professional engineers team to install the machine, train your employee well.

- 4.One year warranty and life-long technical support.

- 5 .24 hours for engineer response.

- 6.Your business relationship with us will be confidential to any third party.

- 7. We welcome customers to visit our factory anytime.

Tel:86-15176910262

Tel:86-15176910262