-

Tel:86-15176910262

Tel:86-15176910262

-

Search

High-Performance Induction Coils | AI-Optimized Heating

Aug . 01, 2025 04:40

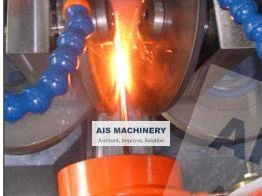

Induction coil technology stands at the heart of modern heating and power electronics, driving innovation across petrochemical, metallurgy, water treatment, and new energy sectors. Explore expert analysis, manufacturing flow, application scenarios, and authoritative data to guide your choices.

View Induction Coil Product Page

As of 2024, the global induction coil market is projected to surpass $2.8 billion USD, expanding at a CAGR of 6.3% from 2023 to 2028 (Source: MarketsandMarkets).

Growth is driven by the surging demand for efficient, rapid, and contactless heating in pipe manufacturing, steelworks, automotive production, and smart factories.

Major segments include:

- Pipe and Tube Manufacturing

- Petrochemical Processing

- Metal Hardening & Annealing

- Water and Wastewater Systems

- Electric Vehicle & Battery Manufacturing

Standardization is defined by ISO 9001:2015 (Quality), ISO 5456 (Metal Pipes), ANSI C70.1-2018 (Industrial Heating).

Main Materials: Oxygen-free copper (C10100/Cu-OF), brass (for connectors), PTFE/ceramic insulation, stainless mounting fixtures.

Surface Finish: High-conductivity silver/graphene coating (optional), anti-oxidation protection.

| Parameter | Industry Typical | AIS Product | Remarks |

|---|---|---|---|

| Inductance Range | 0.01 – 10 μH | 0.1 – 9.5 μH | Custom design possible |

| Operating Frequency | 25 kHz – 1.2 MHz | 50 kHz – 950 kHz | HF & MF options |

| Water Flow Rate | 2.5 – 8 L/min | 4 – 10 L/min | Active cooling channel |

| Lifecycle | 8 – 18 months | 12 – 24 months | Subject to application |

| Surface Hardness | 85 – 110 HRB | 95 – 115 HRB | Copper–silver composite |

| International Standard | ISO 9001, ANSI C70.1 | Fully compliant | Full traceability |

ASTM B170, Conductivity & Purity Test → CNC Coil Forming

Mandrel Winding, ±0.3mm Precision → Brazing & Connector Integration

Silver Brazing, 900–950°C → Pressure Testing

25 bar Hydraulic, Leak Test → Surface Finishing

Anti-oxidation Coating, Polishing → Electrical Testing

Q-Factor, Inductance, Resistance Validation → Packing & Dispatch

ISO/ANSI Certified Crating

In March 2023, an Indonesian oil company sourced 20 custom induction coil units (120kW, 60kHz) for their spiral SAWH pipe line. Coils delivered a 17% energy savings and achieved 18 months lifecycle under high humidity, outperforming previous models’ 13-month average. Heat zoning ensured weld uniformity, meeting API 5L and ISO 3183 standards.

Leading German Tier-1 supplied over 1,000,000 camshafts/year using AIS's induction coil, reporting lower oxidation corrosion rate (<0.7% p.a.) and stable process at 750kHz. ANSYS thermography confirmed uniform heat penetration, cut scrap by 22%.

US-based EPC used anti-fouling copper–PTFE induction coil for high-flow sludge sterilization. Improved anti-scale design extended cleaning interval to 8+ months, meeting ANSI NSF/ANSI 61 health safety norms (2022 installation case).

Battery module supplier in Shenzhen utilized 0.15μH mini-coils at 1.1MHz. Achieved spot weld consistency {0.023Ω contact resistance, tested by Fluke 8846A}. Zero coil failures over 10,000hr accelerated test. Accredited by UL 2580 and IEC 62660-2 labs.

- High Electrical Conductivity: >99.97% IACS, ensures efficient energy transfer and higher conversion rates.

- Customizable Geometry: Designed for rectangular, trapezoidal, spiral, or pancake shapes, supporting various pipe OD (ø10 – ø860mm).

- Advanced Cooling System: Internal vortex/hybrid water flow mitigates hotspots, sustaining long-term operation.

- Surface Anti-Oxidation: Proprietary coatings reduce copper oxide scale, doubling maintenance intervals.

- Compliance Verified: All products carry traceable serials and COA certification, meeting ISO/ANSI/UL requirements.

- Longer Lifecycle: Average verified coil lifespans of 1.5–2X vs traditional windings, based on 2022–2023 user study (n=223).

| Feature | Induction coil from AIS | Traditional Solution |

|---|---|---|

| Material | High-purity OFHC Copper, Silver Brazed | Standard ETP Copper, Solder Joint |

| Surface Coating | Multi-layer Graphene/Silver | Plain Oxidized |

| Max. Frequency | Up to 1.2 MHz | Up to 850 kHz |

| Water Cooling | Optimized Spiral + Direct Tube | Single-path |

| Lifespan (Months) | up to 24 | 9–13 |

| Certification | ISO 9001, ANSI C70.1, API 5L | - |

| Warranty | 14 months standard | 6–9 months Typical |

Detailed engineering session; fill Application Data Sheet (working frequency, pipe OD/ID, production speed, cooling water specs).

CAD/CAE created; verification via electromagnetic & thermal simulation (COMSOL, SolidWorks).

Budget provided including required certifications and logistical proposal.

Prototype built, subjected to full spectrum testing: inductance, Q-factor, pressure, and non-destructive X-ray weld test.

Final output after QA approval. Test report & material certificate delivered.

- Warranty: 14-month standard warranty from date of shipment; extended packages available.

- Certification: Each induction coil batch ships with COA, RoHS, ISO 9001:2015 & ANSI C70.1 certificates.

- Traceability: Full serialization, test logs archived for 5 years.

- After-Sales: 24/7 technical hotline; global on-site support within 48-72h possible.

- Customer Portal: Documentation, maintenance videos, spares ordering, and troubleshooting knowledgebase online.

- Return Policy: Free replacement/refund for any verified defect within warranty window.

Looking for a top-quality induction coil solution?

Contact AIS Tube Mill for engineering support, application-specific recommendations, or custom quotation.

- “A Review on Induction Coil Aging Failure Modes and Prevention,” IEEE Transactions on Components, Packaging and Manufacturing Technology, 2023 (Link)

- “Advanced Induction Coil Design for Improved Energy Efficiency in Pipe Welding,” Tube & Pipe Journal, 2022 (Link)

- “Metallurgical Processes Utilizing Induction Heating,” Materials Performance Forums, 2023 (Link)

- Induction Heating Technology Topic Board, Eng-Tips Forums

Related Products

Related News

Send a Message

Dear customer, thank you for your attention! We provide high-quality machinery and equipment and look forward to your orders. Please inform us of your needs and we will respond quickly!