-

Tel:86-15176910262

Tel:86-15176910262

-

Search

Consumables for Tube and Pipe Welding-How To Use Impeder and Ferrite Core

Dec . 18, 2024 14:26

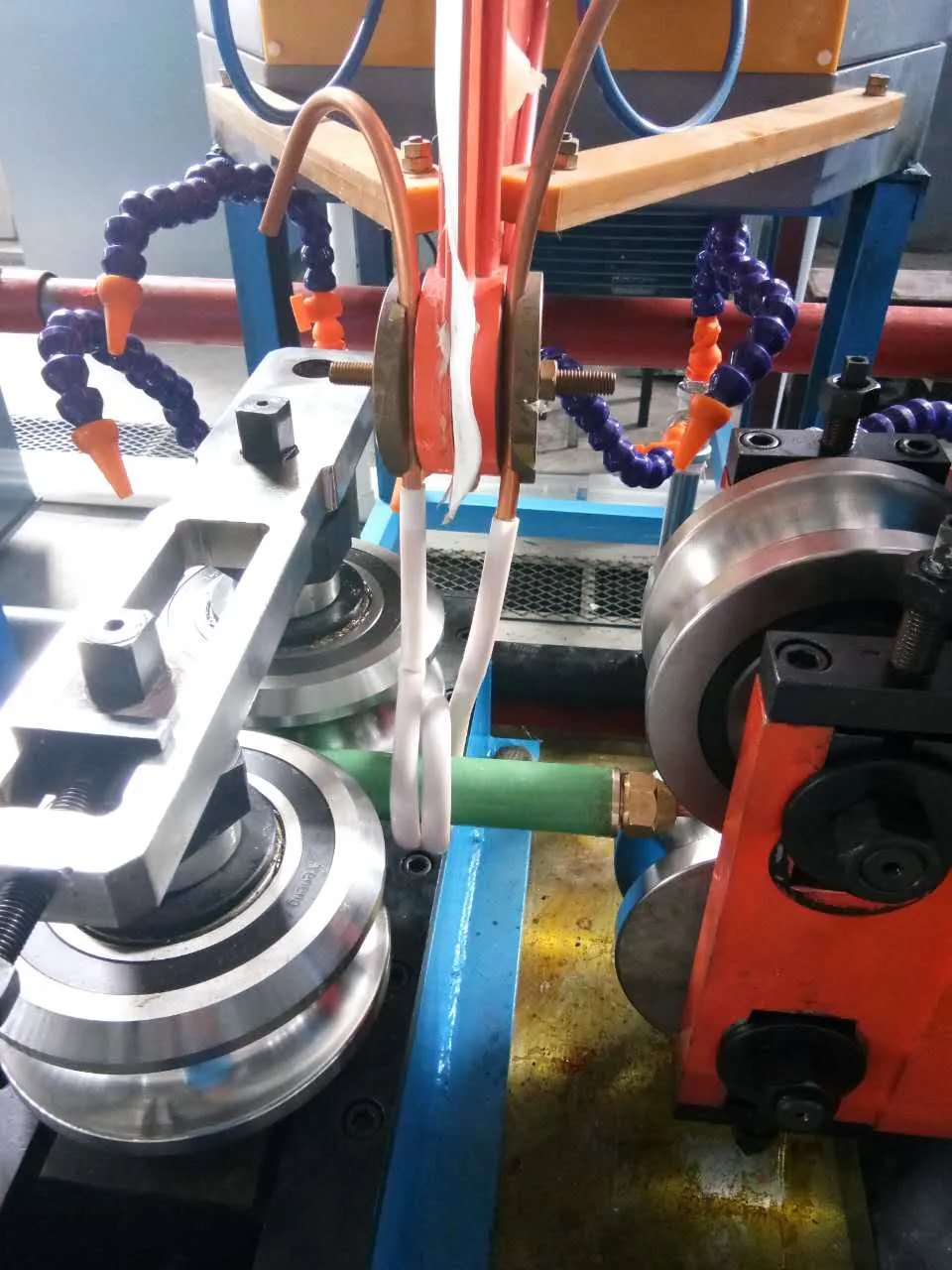

As we all know, in the operation of ERW TUBE MILL, many consumables and spare parts are needed. Today, we will first popularize and explain the Ferrite Cores, Fiberglass Ferrite sleeve and IMPEDER. Do you know how to choose and use them correctly?

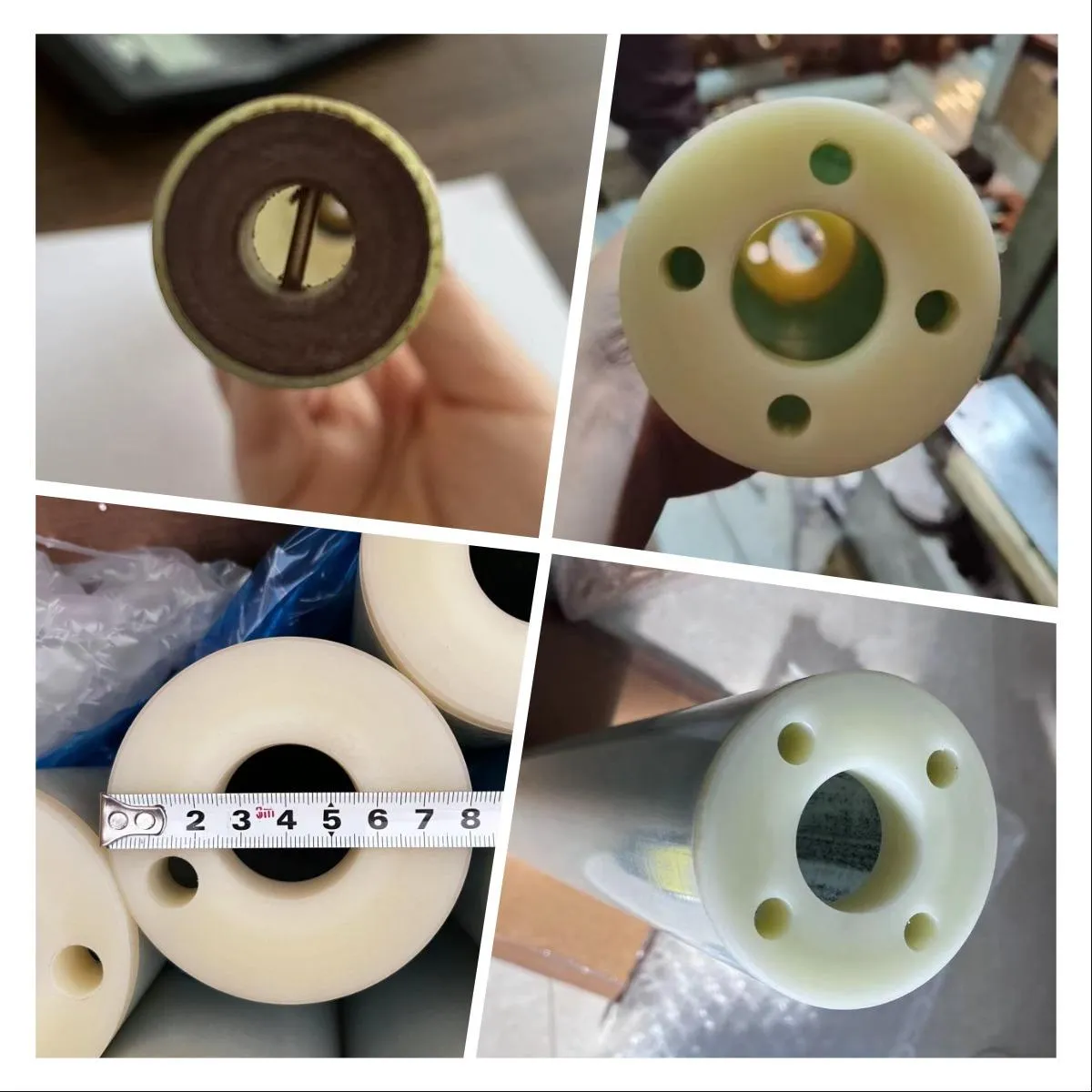

First, the Ferrite Cores . It is used in the pipe seam welding position of the straight seam welded pipe equipment and is used in conjunction with the induction coil on the induction high frequency welder to achieve qualified welding requirements. The advantage is low cost. The disadvantage is that it is easy to break and needs to be replaced immediately after breakage. Replacement requires downtime and affects equipment production.

Second, the Fiberglass Ferrite sleeve is made of fiberglass tube, and the Ferrite cores is usually put into the sleeve for use. The advantage is that the price is economical and it is more durable than using only the Ferrite Cores. Even if the magnetic rod is broken, it will not affect the use.

Third, the impeder is composed of a Ferrite Cores, a Fiberglass Ferrite sleeve, a copper joint, etc. It can be used with a burr removal device inside a steel pipe. The advantages are that it is very durable and not easy to damage, the magnetic effect is excellent, and it is very friendly to high-frequency induction welding. Even if the internal ferrite is damaged, there is no need to worry. It can be replaced during shift changes or other down times, and it can be perfectly matched with the internal burr removal device to solve more product problems. The disadvantage is that it is more expensive than using magnetic rods and magnetic rod sleeves alone.

In addition to the above products, Hebei AIS Machinery also provides more other consumables and spare parts. The following list is for reference. If you need it, please send an email and leave a message for consultation.

Related Products

Related News

Send a Message

Dear customer, thank you for your attention! We provide high-quality machinery and equipment and look forward to your orders. Please inform us of your needs and we will respond quickly!