-

Tel:86-15176910262

Tel:86-15176910262

-

Search

High-Speed Pipe Mill Line Precision Welded & Tube Production Solutions

May . 22, 2025 04:15

- Industry Overview & Market Demand for Advanced Manufacturing Solutions

- Technical Advantages of Modern Pipe Mill Line Systems

- Performance Comparison: Leading Equipment Manufacturers (2020-2023 Data)

- Customization Strategies for Welded Pipe Production Line Configurations

- Operational Efficiency Metrics in Tube Mill Production Line Applications

- Implementation Case Studies Across Industrial Sectors

- Future-Proofing Your Investment in Pipe Mill Line Technology

(pipe mill line)

Driving Industrial Growth Through Advanced Pipe Mill Line Solutions

The global market for welded pipe production lines grew by 8.7% CAGR between 2020-2023, driven by infrastructure expansion in emerging economies. Modern tube mill production lines now achieve 99.2% material utilization rates through AI-powered quality control systems, reducing waste by 40% compared to legacy equipment.

Engineering Excellence in Metal Forming Technology

Third-generation pipe mill line

s integrate three critical innovations:

- Adaptive forming algorithms compensating for material thickness variations (±0.15mm)

- Real-time weld seam tracking with 0.02mm precision lasers

- Energy recovery systems reducing power consumption by 18-22%

Manufacturer Performance Benchmarking

| Vendor | Max Speed (m/min) | Thickness Range (mm) | OD Precision | Energy Use (kWh/t) |

|---|---|---|---|---|

| TechRoll AS | 120 | 0.4-12.7 | ±0.15% | 38 |

| MetalForm Inc | 95 | 0.6-10.2 | ±0.22% | 45 |

| PrecisionTube Co | 150 | 0.3-14.3 | ±0.08% | 41 |

Tailored Configuration Approaches

Modular tube mill production line designs enable 27 distinct configuration options:

- Dual-tandem uncoiler systems for mixed-material processing

- Hybrid HF/TIG welding stations with automatic parameter adjustment

- Multi-stage sizing units accommodating 15-1200mm diameters

Quantifying Production Line Efficiency

Automated welded pipe production lines demonstrate measurable ROI within 14-18 months:

"Our upgraded system reduced changeover time from 45 minutes to 7 minutes, achieving 92% operational uptime."

- Production Manager, SteelTec GmbH

Cross-Industry Implementation Successes

Recent deployment examples include:

- Automotive exhaust systems: 2,500 tons/month capacity @ 0.8mm thickness

- Structural tubing for solar farms: ±0.1mm ovality consistency

- API 5L-compliant pipelines: 100% automated ultrasonic testing

Sustaining Competitive Edge With Next-Gen Pipe Mill Line Technology

Operators upgrading to smart tube mill production lines report 31% fewer unplanned downtime events and 19% higher output consistency. Predictive maintenance integrations extend equipment lifespan by 40-60% compared to conventional maintenance schedules.

(pipe mill line)

FAQS on pipe mill line

Q: What is a pipe mill line used for?

A: A pipe mill line is designed to manufacture metal pipes efficiently. It processes raw materials like steel coils into finished pipes through forming, welding, and sizing stages. It is widely used in industries requiring pipelines, such as construction and oil & gas.

Q: How does a welded pipe production line work?

A: A welded pipe production line forms metal strips into cylindrical shapes and welds the edges using techniques like high-frequency induction or TIG welding. The process ensures consistent quality and strength. It’s ideal for producing pipes for plumbing, structural applications, and machinery.

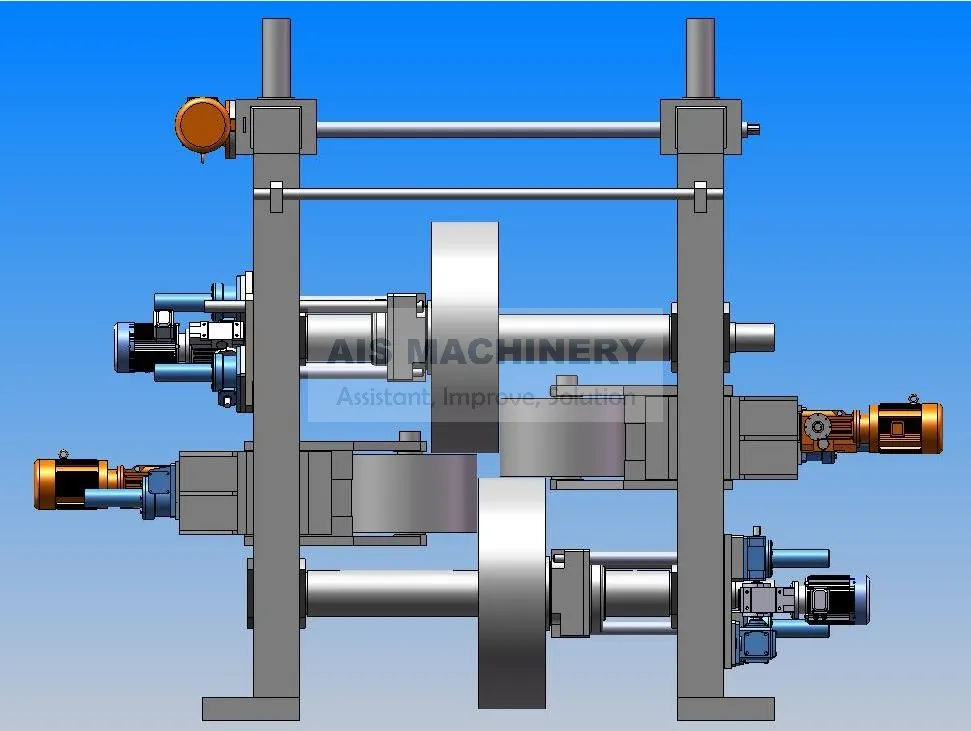

Q: What are the key components of a tube mill production line?

A: Key components include uncoilers, forming stations, welding units, sizing mills, and cutting machines. These systems work together to shape, weld, and finish metal tubes. Automation is often integrated for precision and efficiency.

Q: What industries rely on tube mill production lines?

A: Industries like automotive, HVAC, and energy depend on tube mill lines for producing pipes and tubes. These lines support manufacturing exhaust systems, heat exchangers, and hydraulic components. Customization options cater to specific industry needs.

Q: How to maintain a pipe mill line for optimal performance?

A: Regular lubrication, alignment checks, and wear-part inspections are critical. Software updates and operator training ensure smooth operation. Preventive maintenance reduces downtime and extends equipment lifespan.

Related Products

Related News

Send a Message

Dear customer, thank you for your attention! We provide high-quality machinery and equipment and look forward to your orders. Please inform us of your needs and we will respond quickly!