-

Tel:86-15176910262

Tel:86-15176910262

-

Search

Precision Cutting Made Easy: Flying Cold Saw

May . 08, 2025 16:09

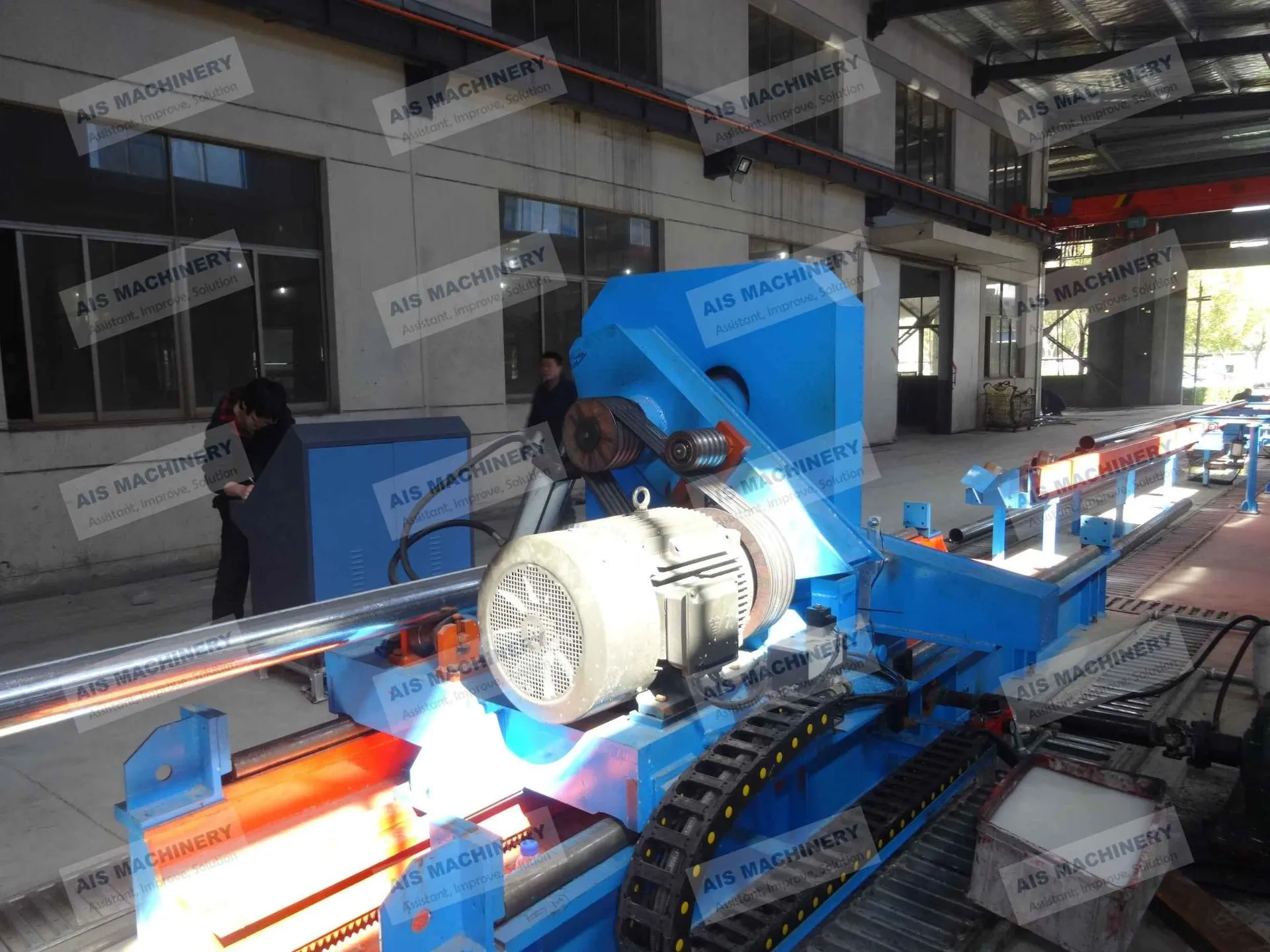

In high-speed metal pipe and tube production lines, the flying cold saw has become an essential cutting solution. Unlike traditional methods that require the line to stop for every cut, a flying cold saw moves synchronously with the material, allowing the cut to be made without halting production. This not only increases efficiency but also significantly reduces waste, making it the preferred choice in continuous tube mill systems.

One of the biggest advantages of the flying cold saw is its ability to make clean and burr-free cuts. It uses a circular saw blade that operates at lower temperatures, preserving the integrity of the metal and eliminating the need for secondary finishing. This cold cutting process results in better-quality products and lower operating costs. For manufacturers aiming for precise lengths and flawless finishes, the flying cold saw delivers exceptional results.

Modern flying cold saws are also equipped with advanced servo motors and CNC controls, allowing for fully automated adjustments during operation. These features ensure that cuts are consistent regardless of pipe thickness or speed of the line. Whether used in large-scale steel pipe production or small-diameter tubing lines, this saw increases productivity while maintaining high precision, which is crucial for large volume outputs.

The flying cold saw is particularly valued for its long blade life and minimal maintenance. Because it generates less heat and vibration, the wear on both the blade and the saw components is reduced. As a result, downtime is minimized and production can continue smoothly. For businesses looking to increase throughput and maintain top-tier quality, the flying cold saw is an investment that pays off.

How Flying Cut Off Saw Improves Production Lines

The flying cut off saw is a key component in automated tube mill lines and continuous roll forming systems. It travels with the moving product and performs cuts while the material stays in motion. This allows manufacturers to maintain line speed without sacrificing cutting precision. In industries where output volume and accuracy are critical, the flying cut off saw provides unmatched efficiency.

The main advantage of a flying cut off saw lies in its ability to increase production speed without compromising quality. It eliminates the traditional stop-and-go motion, helping to prevent material deformation and internal stress that can occur with thermal cutting methods. With its dynamic movement, this system offers seamless performance for high-speed lines producing pipes, tubes, and various profiles.

Using a flying cut off saw also means achieving more consistent part lengths. The saw is typically integrated with encoders and servo systems to accurately track material position and cut timing. This ensures that each section is cut to the exact programmed length, which reduces material loss and saves time on rework. For companies that operate under strict quality standards, such consistency is a huge advantage.

Additionally, modern flying cut off saws come with user-friendly control interfaces, making setup and operation straightforward. Operators can program different sizes, adjust cutting parameters, and monitor performance in real-time. This increases flexibility and reduces dependency on highly skilled labor. In summary, a flying cut off saw transforms cutting from a bottleneck into a competitive advantage on any production line.

Flying Cut Off Machine Makes Precision Automatic

A flying cut off machine is designed to cut pipes and profiles with high accuracy while the line is still running. It eliminates downtime between cuts, which makes it a powerful tool for increasing output in tube mills and roll forming operations. The machine moves in sync with the product and performs the cut using high-speed precision saws or blades, depending on the application.

One of the main benefits of a flying cut off machine is its adaptability. It can be configured for different materials, shapes, and thicknesses, which is essential for manufacturers that work across various product types. Whether cutting round tubes, square pipes, or complex profiles, the flying system ensures accurate, repeatable results every time. This versatility reduces the need for multiple cutting stations and simplifies the production line setup.

The system behind a flying cut off machine is built for durability and high performance. With integrated hydraulic or servo-driven systems, it offers smooth motion control and sharp, clean cuts. Depending on the application, it may use saw blades, shear knives, or other specialized tools for optimal performance. This flexibility ensures that manufacturers can meet market demands quickly and efficiently.

Another significant feature of a flying cut off machine is its ability to reduce heat-affected zones. Unlike hot cutting methods, this machine doesn’t overheat the material, which preserves the structural integrity of the metal. That’s why it’s a popular choice in industries where product quality and mechanical properties are critical, such as automotive, HVAC, and construction tubing. In terms of return on investment, it delivers high productivity with minimal waste.

Why Cold Cutting Saw Technology Is Gaining Attention

The cold cutting saw is gaining popularity across various industries due to its ability to cut metal without generating excessive heat. Unlike abrasive or flame cutting methods, the cold saw operates at lower temperatures, resulting in a smooth, precise cut with minimal material distortion. This is especially valuable in applications that demand clean finishes and high structural integrity.

One key benefit of the cold cutting saw is that it greatly reduces the need for post-processing. Because the cut surface is smoother and free from burrs, there’s less grinding or deburring required afterward. This shortens the production cycle and reduces labor costs. It's an ideal solution for businesses looking to improve efficiency and product quality at the same time.

Another reason companies are shifting to cold cutting saws is their ability to handle a wide range of metals. Whether cutting stainless steel, carbon steel, aluminum, or copper, these saws perform consistently without compromising blade life. The cutting action is clean, quiet, and precise, making it suitable even in demanding environments like aerospace or medical manufacturing.

Modern cold cutting saws come with digital controls and safety systems that ensure accurate and secure operation. Many models also feature automatic feed, clamping, and length setting, making them easy to integrate into automated production lines. For factories focused on reducing energy consumption and improving product yield, cold cutting is a sustainable and forward-looking choice.

Flying Cold Saw FAQs

What is the difference between a flying cold saw and a flying cut off machine?

A flying cold saw typically uses a rotating circular blade with coolant for burr-free cuts, while a flying cut off machine can use various cutting methods, including shear or blade, depending on the material and application.

Why is cold cutting better than hot cutting?

A cold cutting saw doesn’t heat the material during cutting, which helps preserve the metal's mechanical properties and produces a smoother finish with minimal distortion.

Can a flying cut off saw work with high-speed production lines?

Yes, a flying cut off saw is designed specifically to operate with high-speed lines, maintaining synchronization with the moving material for accurate and efficient cutting.

What materials can be processed using a flying cold saw?

A flying cold saw can cut a variety of metals, including stainless steel, carbon steel, and non-ferrous metals, making it suitable for diverse manufacturing needs.

Where can I purchase a reliable flying cold saw system?

You can find durable and high-performance flying cold saw machines by visiting our official website, where you’ll find product details, technical support, and expert assistance in choosing the right model for your operations.

If you're looking to improve the efficiency, quality, and reliability of your metal cutting operations, there's no better solution than a flying cold saw system. These machines offer precise, high-speed cuts while minimizing material waste and maximizing output. Whether you're setting up a new production line or upgrading your existing equipment, a cold cutting solution can bring your operations to the next level. Visit our website today to explore the full range of flying cold saw and flying cut off machine solutions—start cutting smarter and faster with confidence.

Related Products

Related News

Send a Message

Dear customer, thank you for your attention! We provide high-quality machinery and equipment and look forward to your orders. Please inform us of your needs and we will respond quickly!