🔧 Main Functions & Advantages:

-

Uninterrupted Production: Maintains continuous material supply during coil changeover without stopping the main welding line.

-

High Storage Capacity: Stores up to dozens of meters of strip dynamically.

-

High Automation: Equipped with tension sensors and frequency converters, fully integrated with the main line.

-

Versatile Material Compatibility: Suitable for strip thicknesses from 0.8–5.0 mm and widths from 200–800 mm.

🧩 Equipment Composition:

-

Upper and Lower Disc Modules

Steel discs fixed in vertical layout; the strip passes between them to create the storage loop.

-

Tension Detection & Control System

Sensors or encoders monitor strip tension and send feedback to adjust motor speed.

-

Entry Guide System

Aligns and directs the incoming strip into the accumulator path smoothly.

-

Variable Frequency Drive (VFD) System

Synchronizes strip feeding speed with upstream and downstream equipment.

-

Safety Devices

Includes safety guards and emergency stop switches to ensure operator safety.

⚙️ Technical Specifications (Customizable)

🔍 Comparison: Disc Accumulator vs. Loop Cage

Conclusion: The Disc Type Accumulator is better suited for modern ERW tube mills with high automation, space-saving requirements, and stable strip handling needs.

🌀 Working Principle:

After uncoiling and leveling, the strip enters the upper disc group, winds through several fixed discs, and exits from the bottom. This forms a vertical buffer area that automatically adjusts feeding speed based on mainline status. During coil changeover, the accumulator speeds up to maintain continuous output, ensuring non-stop production.

EQUIPEMENT DE RELATION

Nous fournissons tout l'équipement pour la section d'entrée du laminoir à tubes :

Voiture à bobine

Dérouleur à tête simple et double et dérouleur hydraulique et pneumatique

Bras d'éplucheur et de maintien du rouleau

Machine à aplatir

Cisailleuse et soudeuse bout à bout automatique et semi-automatique

Vertical Cage Accumulator & Horizontal Loop Accumulator & Landing Horizontal Spiral Loop Accumulator

NOTRE SERVICE

Pourquoi nous choisir?

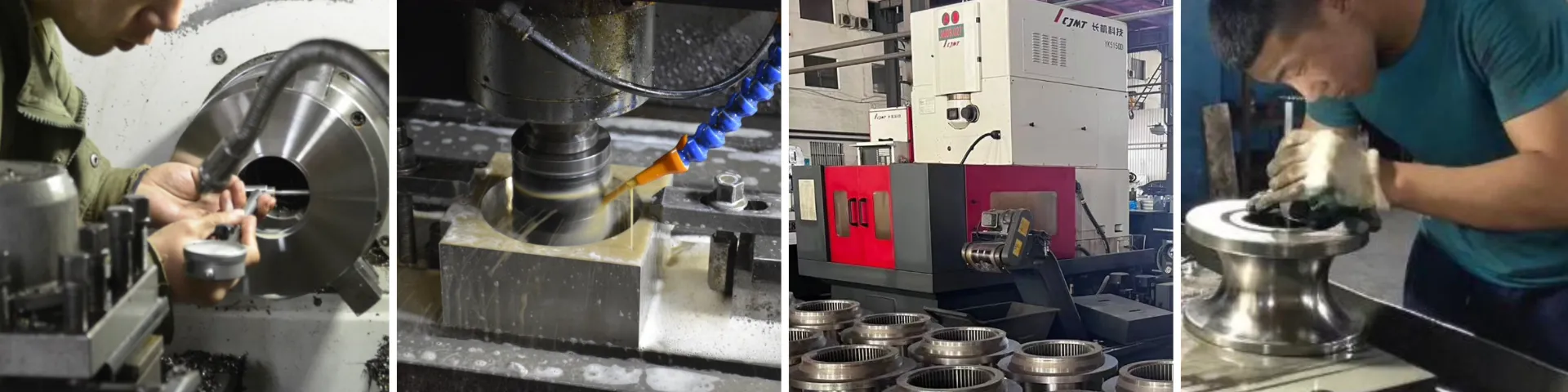

Technologie de pointe, qualité fiable, excellent service !

Conception optimisée, sélection de matériaux de haute qualité !

Garantie du processus de traitement thermique !

Engrenage conique hélicoïdal, accouplement à tambour et cémentation.

Trempe des dents d'engrenages.

Système d'entraînement stable, efficace et portable avec moins de bruit.

Haute précision, résistance à l'usure et longue durée de vie des rouleaux.

Tous les tours mécaniques, les rainures de clavette sont positionnés et fraisés par CNC.

Service après-vente

1. Nous livrerons la machine et fournirons les documents à temps pour nous assurer que vous pouvez obtenir la machine rapidement

2. Lorsque vous avez terminé les conditions de préparation, notre équipe d'ingénieurs du service après-vente rapide et professionnel se rendra dans votre usine pour installer la machine, vous remettre le manuel d'utilisation et former votre employé jusqu'à ce qu'il puisse bien utiliser la machine.

3. Nous offrons une garantie d'un an et un support technique à vie.

4. Un personnel bien formé et expérimenté répondra à toutes vos demandes en anglais et en chinois

5,24 heures pour l'intervention de l'ingénieur.

6. Votre relation commerciale avec nous sera confidentielle envers tout tiers.

Contrôle de qualité

Nous disposons d'un département de qualité unique, qui garantit que le matériau des matières premières est bon et garantit le bon fonctionnement de la machine.

Tél. : 86-15176910262

Tél. : 86-15176910262