🔧 Main Functions & Advantages:

-

Uninterrupted Production: Maintains continuous material supply during coil changeover without stopping the main welding line.

-

High Storage Capacity: Stores up to dozens of meters of strip dynamically.

-

High Automation: Equipped with tension sensors and frequency converters, fully integrated with the main line.

-

Versatile Material Compatibility: Suitable for strip thicknesses from 0.8–5.0 mm and widths from 200–800 mm.

🧩 Equipment Composition:

-

Upper and Lower Disc Modules

Steel discs fixed in vertical layout; the strip passes between them to create the storage loop.

-

Tension Detection & Control System

Sensors or encoders monitor strip tension and send feedback to adjust motor speed.

-

Entry Guide System

Aligns and directs the incoming strip into the accumulator path smoothly.

-

Variable Frequency Drive (VFD) System

Synchronizes strip feeding speed with upstream and downstream equipment.

-

Safety Devices

Includes safety guards and emergency stop switches to ensure operator safety.

⚙️ Technical Specifications (Customizable)

🔍 Comparison: Disc Accumulator vs. Loop Cage

Conclusion: The Disc Type Accumulator is better suited for modern ERW tube mills with high automation, space-saving requirements, and stable strip handling needs.

🌀 Working Principle:

After uncoiling and leveling, the strip enters the upper disc group, winds through several fixed discs, and exits from the bottom. This forms a vertical buffer area that automatically adjusts feeding speed based on mainline status. During coil changeover, the accumulator speeds up to maintain continuous output, ensuring non-stop production.

RELATION EQUIPMENT

We provides all equipment to tube mill entry section:

Coil Car

Single And Double Heads Un-coiler & Hydraulic And Pneumatic Un-coiler

Peeler and hold down roll arm

Flattening Machine

Automatic and Semi Auto Shearer & Butt Welder

Vertical Cage Accumulator & Horizontal Loop Accumulator & Landing Horizontal Spiral Loop Accumulator

OUR SERVICE

Why Choose Us?

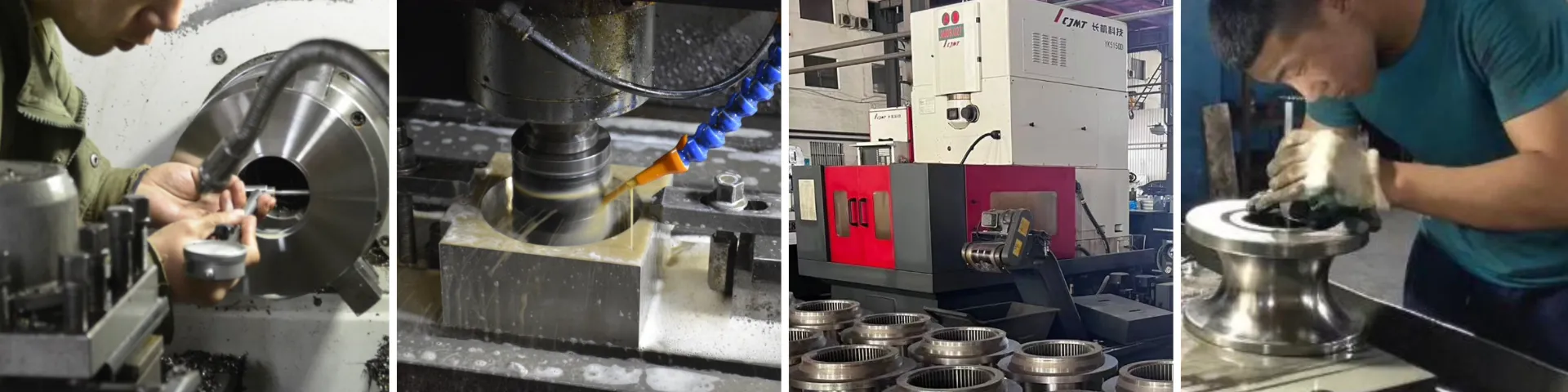

Leading Technology, Reliable Quality, Excellent Service!

Optimized Design, High quality material select!

Heat treatment process guarantee!

Spiral bevel gear, drum gear coupling and carburization.

Gear teeth quenching.

Driven system stable, efficient and wearable with lower noise.

High precision wear resisting and Long life of rollers.

All the machine Lathes, Key Grooves are positioned and Milled by CNC.

After-sales service

1.We will delivery the machine and provide the documents on time to make sure you can get the machine quickly

2.When you finish the Preparation conditions, Our fast and professional aftersales service engineer team will go to your factory to install the machine, give you the operating manual, And train your employee until they can operate the machine well.

3.We provide one year warranty and life-long technical support.

4.Well-trained & experienced staff are to answer all your inquiries in English and Chinese

5 .24 hours for engineer response.

6.Your business relationship with us will be confidential to any third party.

Quality Control

We have the single quality department, that make sure the material of the raw materials is good, and ensure the machine running smoothly.

Tel:86-15176910262

Tel:86-15176910262